iiotecos: IIoT-Software für die digitalisierte spanende Produktion

iiotecos ist eine IIoT-Software, die Ihre Maschinen anbindet, Ist-Zustände von Werkzeugen, Anlagen, Werkstücken etc. in Form von digitalen Zwillingen erfasst, Daten aggregiert und visualisiert. iiotecos kann unternehmensintern oder unternehmensübergreifend genutzt werden.

Eine IIoT-Software kann Potenziale Ihrer Fertigung identifizieren und heben

Sicherlich optimieren Sie Ihre Produktion laufend, doch das größte Potenzial für Optimierungen und inbesondere Kosteneinsparungen liegt in Ihren Produktionsdaten. Mittels einer echtzeitnahen Inline-Qualitätskontrolle können Sie Ressourcen einsparen und die Qualität verbessern – ohne zusätzlichen Platzbedarf oder personellen Aufwand. Kommt es darüber hinaus zu einer unternehmensübergreifenden Zusammenarbeit mit Ihren Kunden oder Zulieferern, entstehen besonders große Synergien.

Ist Ihre Produktion bereit für das Industrial Internet of Things?

Entdecken Sie Industrie 4.0 für die spanende Metallbearbeitung

Die IIoT-Plattform CuttingEdge ist speziell auf die Bedürfnisse von Herstellern und Nutzern aus dem Bereich der spanenden Bearbeitung zugeschnitten. Die Plattform hilft Unternehmen dabei, bis zu 20 Prozent Kosten in der Produktion zu sparen.

Wir haben im Projekt MAI ILQ2020 die Wirkketten – angefangen von den Erkenntnissen im Data Analytics bis hin zu den ökonomischen Potenzialen – im Detail analysiert. Dabei zeigen sich insbesondere in der automatisierten Inline-Qualitätskontrolle, Predictive Maintenance und Prozessoptimierung die größten Potenziale.

IIoT-Software und Plattform für die Composites-Industrie

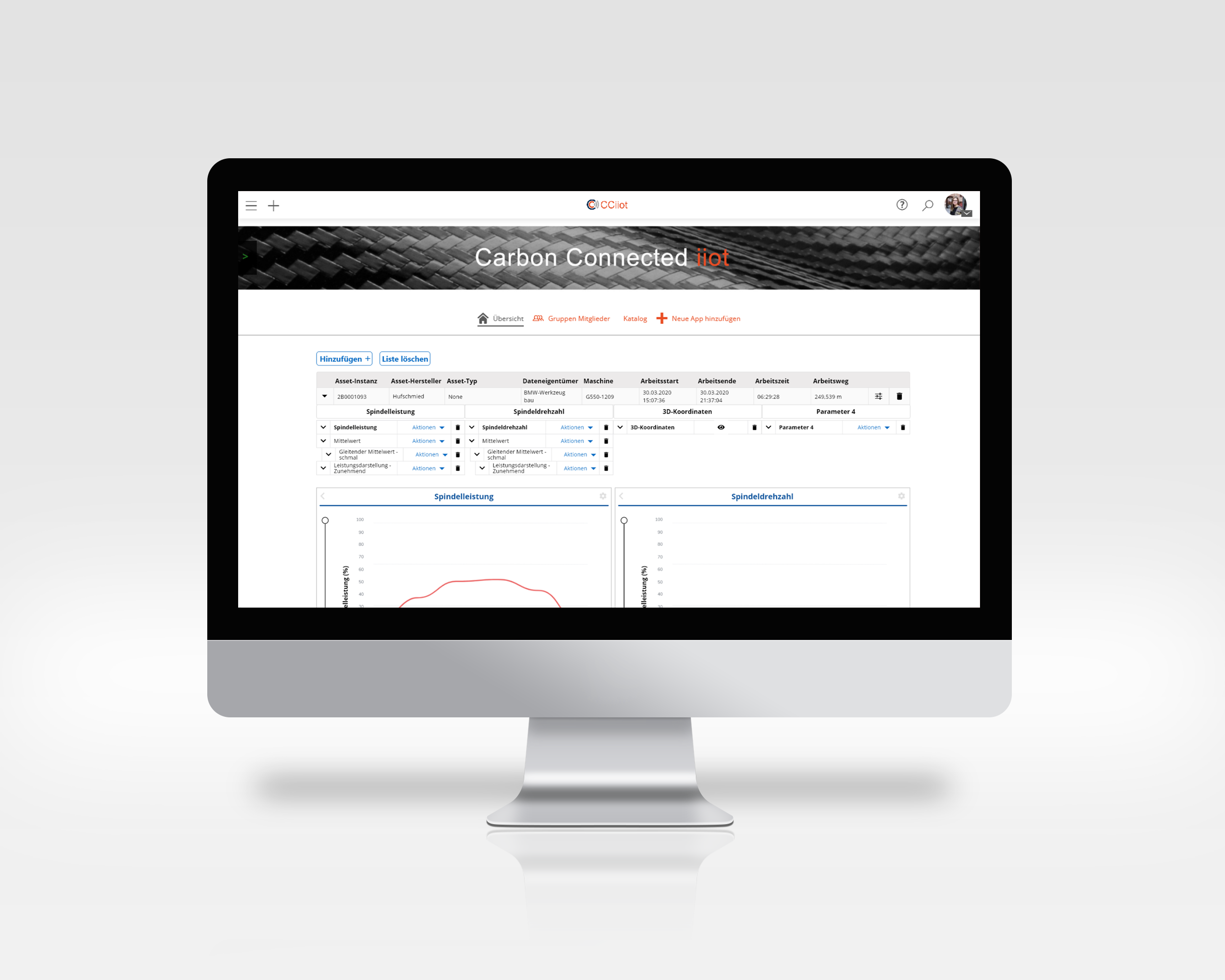

Mit Hilfe der Plattform CCiiot können Unternehmen ihre Produktion effizienter und nachhaltiger gestalten, Produkte optimieren, den Kundendienst digitalisieren und vieles mehr. Der Schlüssel: unternehmensübergreifende Zusammenarbeit und ausgeklügelter Know-How-Schutz.

Mit iiotecos können unsere Nutzer sich selbständig vernetzen und zusammenarbeiten. Als Industrienetzwerk müssen wir dabei allerdings Vertraulichkeit und Sicherheit gewährleisten. Die Plattform ermöglichtes uns, flexible Angebote aufzubauen und Zugriffsrechte detailliert zu steuern.

Sensorik

iiotecos selbst beinhaltet keine Sensorik, d. h., wir binden Ihre bereits vorhandene Sensorik an unser Industrie 4.0-Hub an oder können Ihnen eine kompatible Sensortechnik unserer Partner empfehlen.

Ein Werkzeugbruch führt zu einer ungeplanten Produktionsunterbrechung und ggf. zu Schäden am Bauteil. Die Signale hierfür, Körperschall und Spindelleistung, kündigen sich als Abweichung ggü. einem Referenzwert an. Mit Hilfe von künstlicher Intelligenz kann zukünftig der Werkzeugbruch vorhergesagt werden, um entsprechende Gegenmaßnahmen einzuleiten.

IIoT-Sicherheit

Wir wissen, dass die Daten Ihrer Systeme erfolgskritisch für Ihr Unternehmen sind. Deswegen setzen wir auf höchste Sicherheitsstandards, ein detailliertes Rollen- und Rechtekonzept sowie das Prinzip der Datensouveränität. Das heißt: Sie allein bestimmen, wer welche Daten sehen darf und können dies bis ins Detail abstimmen.

Die Spindelleistung gegenüber dem Weg kann standardmäßig dem Fräswerkzeughersteller übermittelt werden. Der kann die Leistungsfähigkeit seiner Werkzeuge beurteilen und diese verbessern. Für genauere Informationen ist die Darstellung im Raum erforderlich, die bei der Einzelteilfertigung aber dem Produktionsschutz unterliegt. Die 3D-Darstellung wird daher nur auf Anforderung und in Einzelfällen freigegeben.

Analyse

Damit Sie den größten Nutzen aus den Daten Ihrer Digitalen Zwillinge ziehen können und Sie das volle Potenzial ausschöpfen, bieten wir Ihnen verschiedene Möglichkeiten der Datenvisualisierung und -analyse an.

Use Cases und Artikel zum Thema

iiotecos bietet flexible Anwendungsmöglichkeiten

Eine IIoT-Plattformen bietet Ihnen zahlreiche Anwendungsmöglichkeiten wie z. B. Inline-Qualitätskontrolle, Predictive Maintenance oder einen digitalisierten Kundenservice.

Kundenservice digitalisieren

Besteht tatsächlich ein Anspruch auf Gewährleistung? Dank ecosiiot können in Streitfragen die Fakten sprechen. Zulieferer und OEM begegnen sich auf Augenhöhe.

Data Analytics

Sehen Sie tabellarische, zwei- und dreidimensionale Datenmodelle und nehmen Sie daran beliebige Auswertungen vor.

Inline-Qualitätskontrolle

Überwachen Sie die Qualität in Ihrer Produktion laufend und erhalten Sie so einen Überblick über Qualitätsfaktoren im gesamten Herstellungsprozess. Die Qualitätskontrolle nach der Produktion entfällt.

Fachkräftemangel ausgleichen

Dank optimierter Prozesse, können Sie Arbeitskräfte beispielsweise in der Nachbearbeitung einsparen und Ressourcen an der Maschine gezielter einsetzen.

Predictive Maintenance

Führen Sie Wartungen nach tatsächlichem Bedarf und nicht nach vorsorglich gewählten Intervallen aus. So können Sie auch Schäden an Anlagen vorbeugen.

Pay per Use

Dank der Transparenz darüber, welche tatsächliche Einsatzdauer ein Werkzeug hat, wird es möglich, nicht nur pro Stück abzurechnen, sondern ggf. auch neue Geschäftsmodelle, wie Pay-Per-Use (PPU) einzuführen.